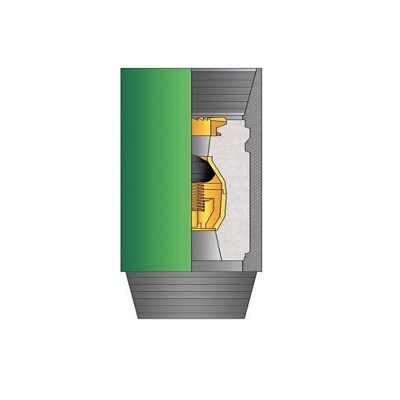

The orifice check valve is designed to equip the bottom of casing strings to ensure self-filling of the lowered strings with drilling fluid from the well without overflowing it from the string to the wellhead. To perform the function of the “stop” ring and ensure hermetic fit of separating plugs on it in the process of pushing the cement slurry into the annular space and to prevent the reverse flow of fluid from the well into the string after cementing is completed. Valves are produced with the following threads: OTTM, OTTG, BTS, short triangular, and according to API standards.

Specifications

| Model | Max work pressure, MPa | Full diameter, mm | Inner diameter of valve body, mm | Sphere diameter, mm | Height, mm |

| BVU-140 | 25 | 159 | 118,7 | 76 | 405 |

| BVU-168 | 25 | 188 | 144,1 | 76 | 420 |

| BVU-178 | 25 | 198 | 176 | 76 | 398 |

| BVU-194 | 25 | 216 | 172 | 76 | 395 |

| BVU-219 | 15 | 245 | 195 | 76 | 420 |

| BVU-245 | 15 | 270 | 220 | 76 | 420 |

| BVU-273 | 10 | 299 | 249 | 76 | 415 |

| BVU-299 | 10 | 299 | 249 | 76 | 415 |

| BVU-299 | 10 | 324 | 274,5 | 76 | 405 |

| BVU-324 | 10 | 351 | 300 | 76 | 405 |

| BVU-340 | 10 | 351 | 300 | 76 | 405 |